In the manufacturing industry, every inch of material matters. Waste not only impacts production costs…

How Industrial Engineering Can Optimize Your Manufacturing Processes

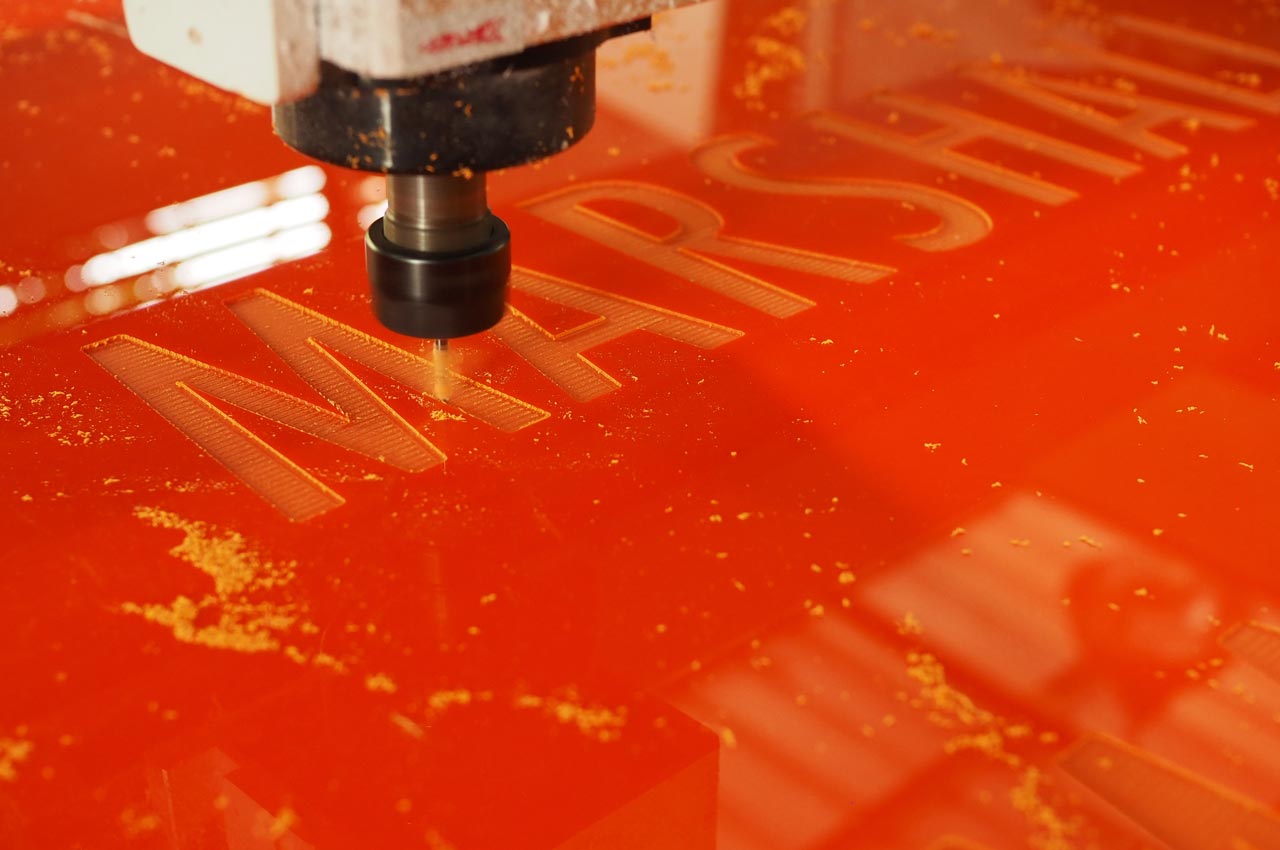

Industrial engineering is a key discipline in optimizing manufacturing processes, focused on improving efficiency, reducing costs, and increasing productivity. Through workflow analysis, lean implementation, and continuous improvement, companies can transform their operations to be more competitive. In this blog, we will explore how industrial engineering can enhance manufacturing processes and deliver tangible benefits.

- Workflow Analysis

The first step in optimizing any manufacturing process is a detailed analysis of workflows. Industrial engineers examine each step of production to identify inefficiencies, bottlenecks, and areas for improvement. This analysis is carried out using techniques such as process mapping and simulation, giving companies a clear view of how work moves through the production chain.

A practical example is the use of simulation software to model different production scenarios. This tool allows companies to predict the impact of changes in plant layout, resource allocation, or the introduction of new technologies, helping make data-driven decisions.

- Lean Solutions Implementation

One of the main tools industrial engineering uses to optimize manufacturing is the implementation of lean solutions. The lean approach seeks to eliminate waste in all forms: time, materials, effort, and costs. Techniques such as Just-in-Time (JIT), kanban, and flow production help reduce excess inventory, minimize waiting times, and improve product quality.

Companies that have adopted lean principles have seen drastic improvements in productivity and efficiency. A success story is Toyota, a pioneer in lean manufacturing, which improved its processes, resulting in shorter delivery times and higher-quality products at a lower cost.

- Continuous Improvement

Another core principle of industrial engineering is continuous improvement, a systematic approach aimed at perfecting processes incrementally. By implementing methodologies such as Kaizen, companies can consistently identify and resolve issues, fostering a culture of improvement throughout the organization.

A practical example of continuous improvement is General Electric, which adopted the Six Sigma methodology to reduce variability in its processes and improve product quality. This strategy allowed the company to save millions of dollars by eliminating defects and optimizing operations.

- Success Stories in Manufacturing Optimization

Many companies have experienced significant success by applying industrial engineering principles to optimize their manufacturing processes.

- Boeing, for instance, implemented process simulation and lean manufacturing techniques to reduce the production time of its airplanes. As a result, it improved delivery times and reduced operating costs.

- Amazon, a leader in logistical efficiency, uses industrial engineering to continuously enhance its distribution systems. With the help of lean solutions and automation, it has optimized its warehouses, achieving faster deliveries at lower costs.

- Cost Savings and Productivity Increase

Optimizing manufacturing processes through industrial engineering directly translates to cost savings and increased productivity. By eliminating non-value-added activities and improving workflow, companies can reduce production time and resource use, leading to lower operating costs.

Moreover, better resource allocation and more efficient planning result in increased productivity. Companies that adopt this approach can produce more with the same resources, allowing them to scale operations without incurring additional costs.

Industrial engineering is an essential component for optimizing manufacturing processes in modern companies. Through workflow analysis, lean solutions implementation, and a focus on continuous improvement, organizations can enhance efficiency, reduce costs, and increase productivity. By adopting these techniques, companies will be better equipped to face the challenges of a competitive and ever-changing market.