In the manufacturing industry, every inch of material matters. Waste not only impacts production costs…

The Advantages of Custom Metal Fabrication in Modern Manufacturing

In the modern manufacturing era, custom metal fabrication has become a key component for businesses seeking personalization, efficiency, and cost reduction. This process allows companies to design and create unique parts tailored to specific needs, offering a significant advantage in a competitive environment. Below, we explore the main benefits of custom metal fabrication.

- Customization and Flexibility

One of the greatest benefits of custom metal fabrication is the ability to fully customize parts. Companies can design components that meet customer specifications exactly, allowing for the creation of unique products that can’t be found in standard solutions.

The flexibility of custom fabrication allows for design modifications on the fly, which is crucial in industries where requirements can change rapidly. This ability to adapt to customer needs not only enhances satisfaction but also strengthens long-term client relationships.

- Increased Precision

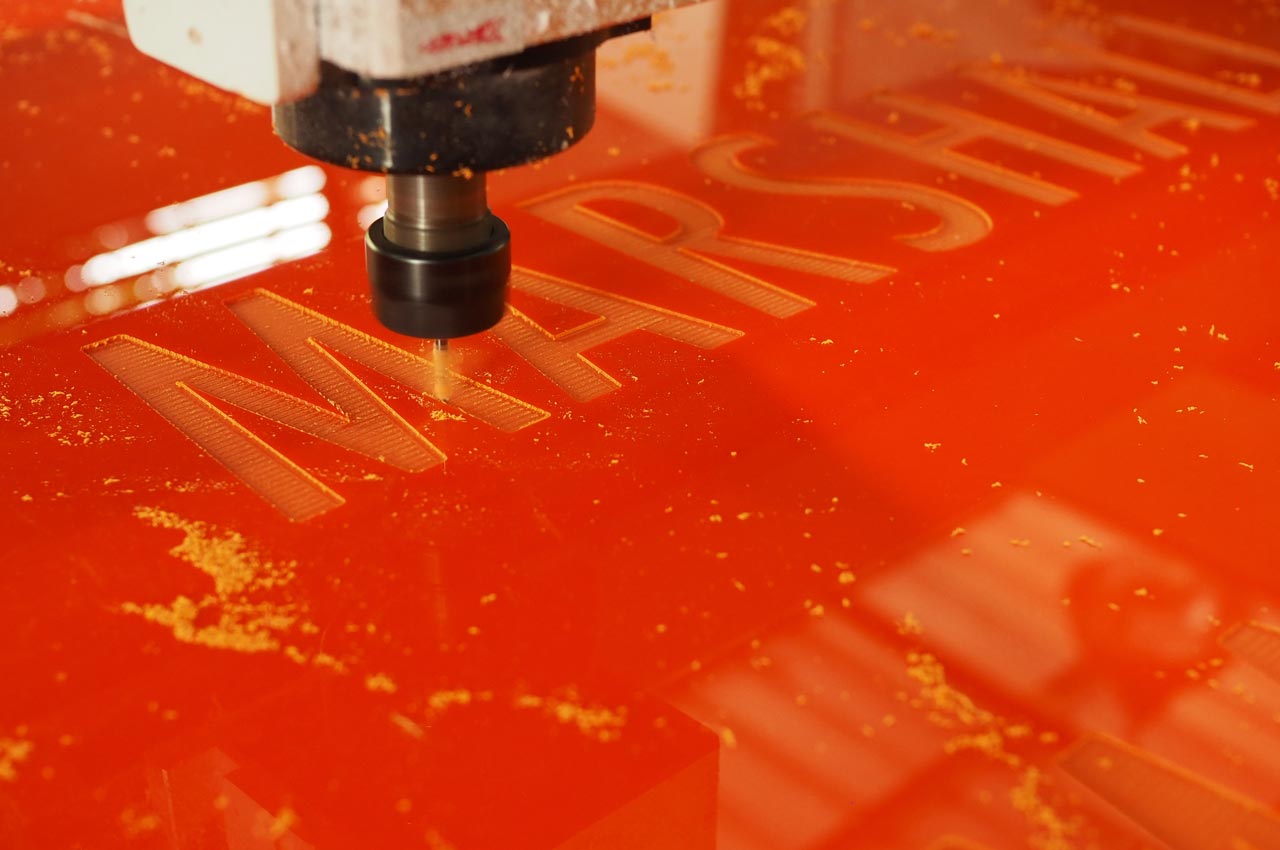

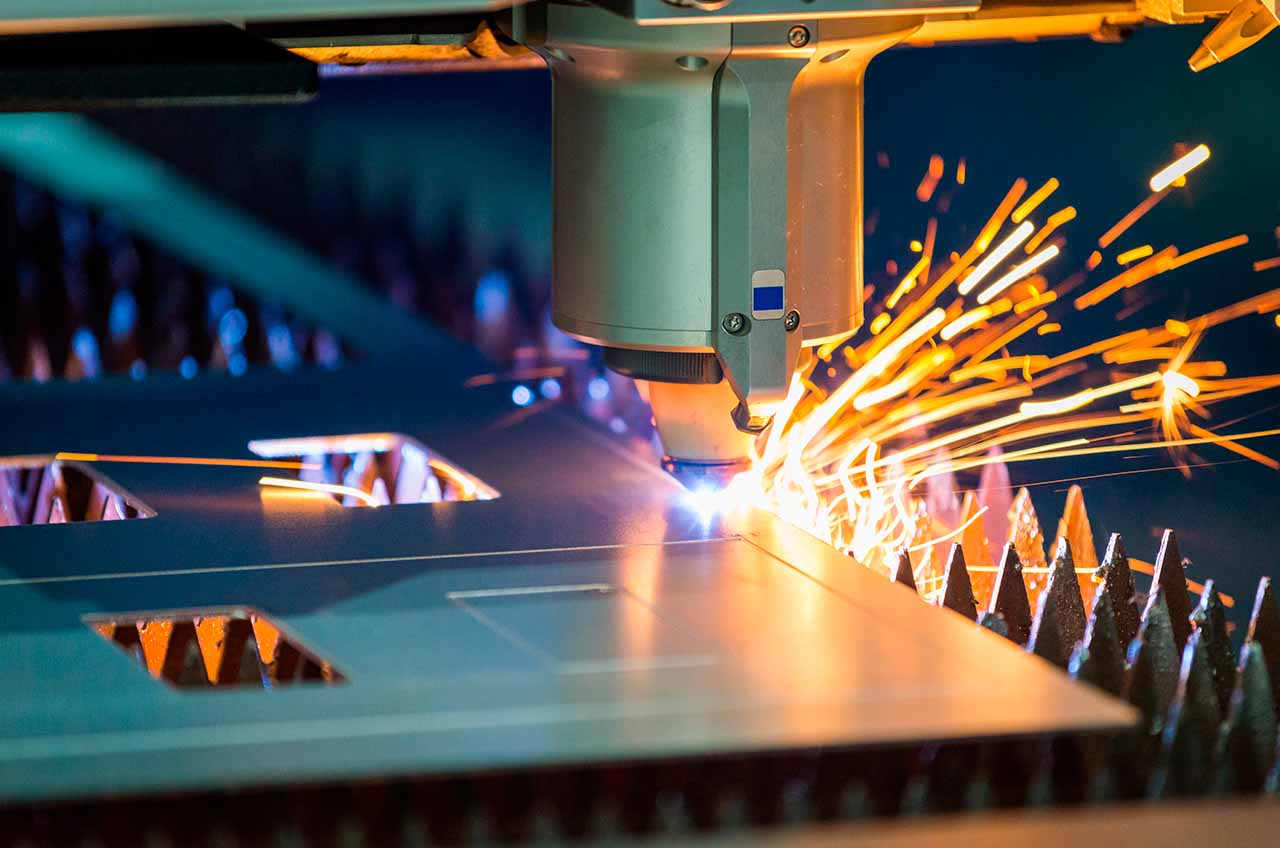

Custom metal fabrication utilizes advanced technologies such as laser cutting, precision welding, and CNC machinery, ensuring extreme accuracy at every stage of production. These tools enable manufacturers to produce parts with very tight tolerances, essential in industries like aerospace, automotive, and medical, where precision is critical to product performance.

By creating custom parts with high precision, the need for post-production adjustments is reduced, saving time and costs in assembly and ensuring maximum quality in the final product.

- Cost Optimization

While custom metal fabrication may seem expensive at first glance, it can actually result in cost savings in the long run. The ability to produce exactly what is needed eliminates excess inventory, reducing material waste and storage costs.

Additionally, by fabricating parts that fit perfectly into existing systems and processes, assembly issues are minimized, and costly repairs are avoided, optimizing time and resources.

- Improved Operational Efficiency

Custom fabrication allows companies to create parts specifically designed to enhance operational efficiency. This includes components that optimize machinery and structures that facilitate production. By using high-quality materials and advanced techniques, custom parts not only last longer but also perform better, reducing downtime and improving workflow.

Moreover, custom metal fabrication makes it easier to integrate new technologies and systems into existing processes, enabling companies to stay competitive and quickly adapt to market innovations.

- Compliance with Standards and Quality Requirements

In many industries, meeting specific regulations and high-quality standards is essential. Custom metal fabrication allows the creation of parts that comply with strict regulations, from safety certifications to environmental standards.

By working with experienced manufacturers in custom processes, companies can ensure that each part not only meets regulations but also fits the specific needs of the industry.

Custom metal fabrication offers a variety of key advantages in modern manufacturing, from customization and precision to cost reduction and improved operational efficiency. In an increasingly competitive market, the ability to design unique parts tailored to specific needs allows businesses to not only meet customer demands but also optimize their own production processes.