In the manufacturing industry, every inch of material matters. Waste not only impacts production costs…

The Future of Industrial Engineering Services: Trends and Innovations

Over the past decade, industrial engineering services have undergone a radical transformation driven by technological advancements. This sector is in a constant state of evolution, with emerging trends that are redefining production processes, improving efficiency, and optimizing resources. Below, we explore some of the key innovations shaping the future of industrial engineering.

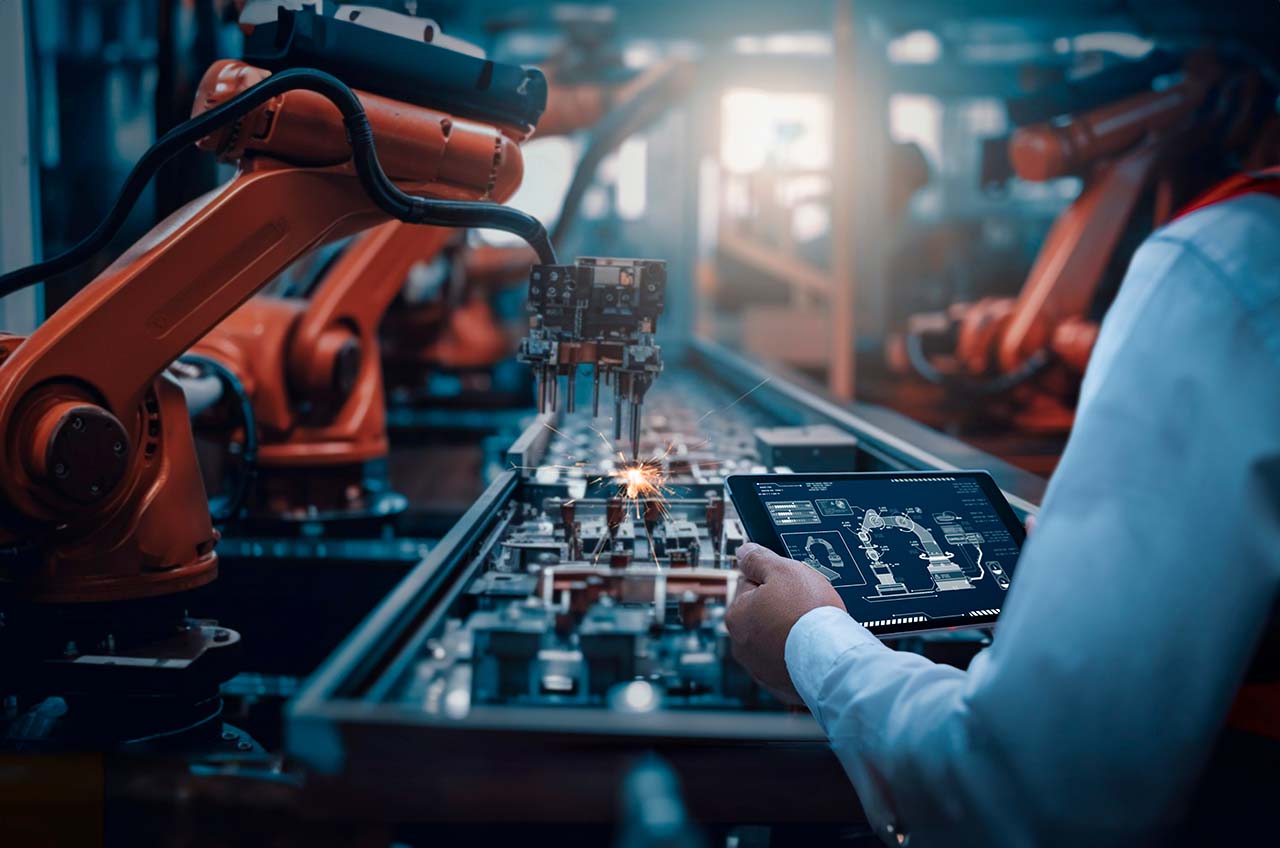

- Smart Automation

Automation is no longer a new concept, but its integration with advanced technologies such as artificial intelligence (AI) and machine learning has unlocked its full potential. Automated systems are now smarter, capable of making decisions based on large amounts of data. This allows for greater flexibility in production processes, reducing human errors and improving operational efficiency.

A notable example is the introduction of collaborative robots, or cobots, which work alongside humans in factories, optimizing repetitive and hazardous tasks. These cobots not only enhance safety but also increase productivity.

- Digitalization and Digital Twins

Digitalization is transforming industrial engineering by enabling a data-driven approach to process analysis and improvement. Digital twins are virtual representations of physical systems that allow companies to simulate, analyze, and optimize machine and process performance before implementing changes in the real world.

With this technology, companies can anticipate problems and optimize predictive maintenance, reducing downtime and improving operational efficiency. Moreover, digital twins facilitate mass customization and enable companies to quickly adapt to changing market demands.

- Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) is enabling factories to become smarter and more connected environments. Through embedded sensors and interconnected devices, industrial systems can collect and share real-time data, enabling faster and more accurate decision-making.

This enhanced connectivity not only optimizes production but also enables the creation of smart factories, where equipment can self-adjust to improve performance and reduce operational costs.

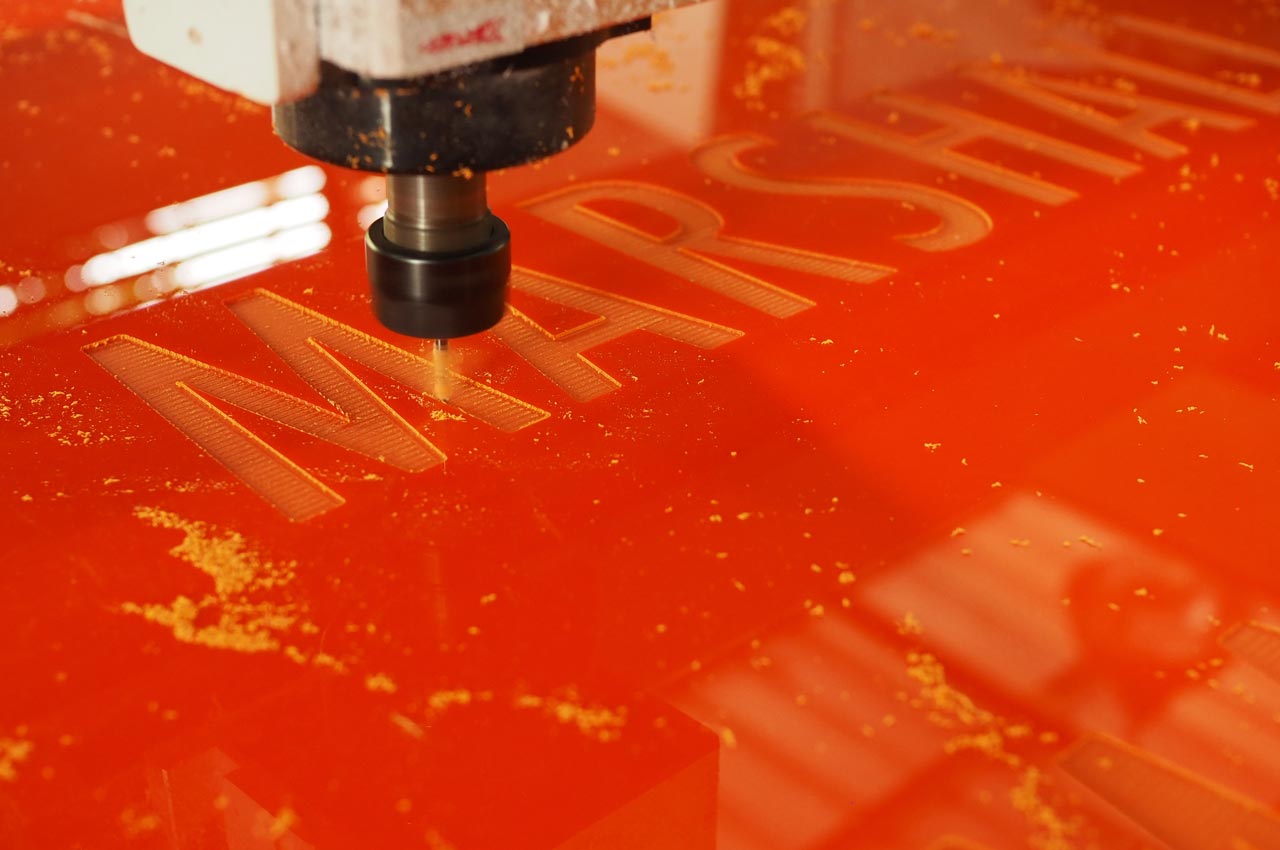

- Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is revolutionizing the way products are designed and manufactured. This technology allows companies to create complex parts and components that would be impossible or very costly to produce using traditional methods.

In industrial engineering, additive manufacturing offers the ability to produce rapid prototypes, reduce material waste, and shorten production times, thereby driving innovation and customization.

- Sustainability and Energy Efficiency

With increasing environmental awareness, industrial engineering companies are adopting more sustainable technologies to reduce their carbon footprint. Advances in renewable energy, such as solar and wind power, are being integrated into industrial operations to lower energy consumption.

Additionally, sustainable engineering includes designing products and processes that minimize waste and optimize the use of natural resources, contributing to a more eco-friendly and responsible approach to production.

The future of industrial engineering services is clearly marked by the integration of advanced technologies that enhance efficiency, production, and sustainability. Smart automation, digital twins, IIoT, additive manufacturing, and sustainability are just a few of the trends that will continue to transform the industry in the coming years. Companies that embrace these innovations will be better positioned to lead in a competitive and ever-changing market.